Welding Positioners

-

0%

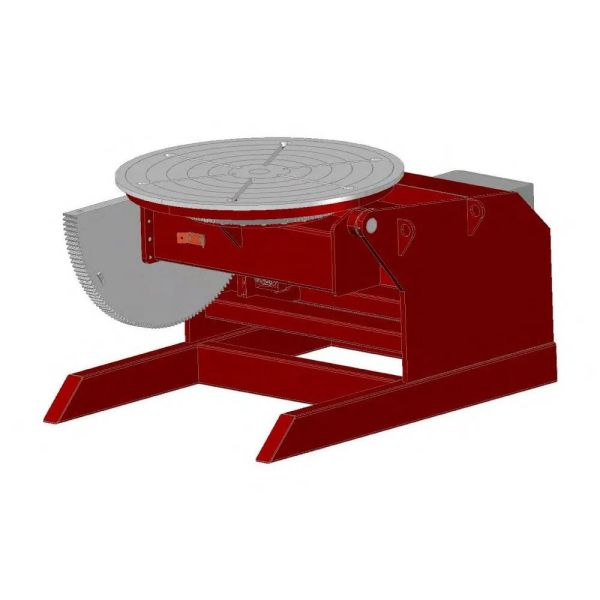

Key Plant Automation VP0.7 700KG Fixed Height Welding Positioner

POA: Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have.

-

0%

Key Plant Automation VP1.5 1.5 Tonne Fixed Height Welding Positioner

POA: Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have.

-

0%

Key Plant Automation VP3 3 Tonne Fixed Height Welding Positioner

POA: Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have.

-

0%

Key Plant Automation VP5 5 Tonne Fixed Height Welding Positioner

POA: Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have.

-

0%

Key Plant Automation VP10 10 Tonne Fixed Height Welding Positioner

POA: Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have.

-

0%

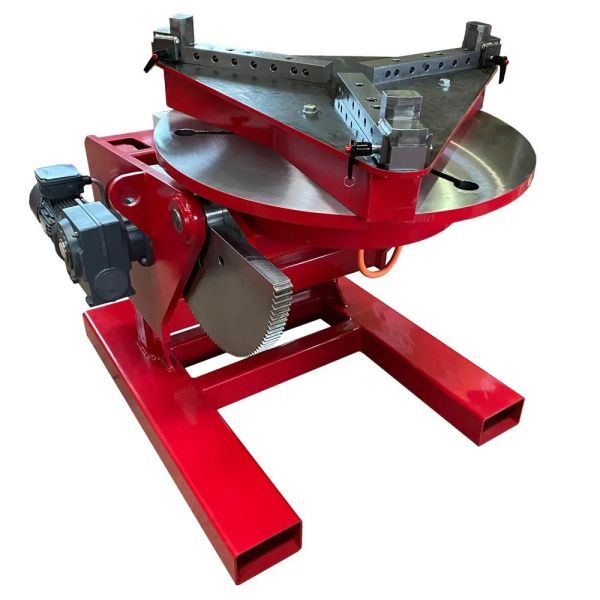

Key Plant Automation AHVP15 15 Tonne Adjustable Height Welding Positioner

POA: Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have.

-

0%

Key Plant Automation AHVP10 10 Tonne Adjustable Height Welding Positioner

POA: Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have.

-

0%

Key Plant Automation AHVP5 5 Tonne Adjustable Height Welding Positioner

POA: Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have.

-

0%

Key Plant Automation AHVP3 3 Tonne Adjustable Height Welding Positioner

POA: Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have.

-

0%

Key Plant Automation AHVP1.5 1.5 Tonne Adjustable Height Welding Positioner

POA: Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have.

-

0%

Key Plant Automation AHVP0.7 700KG Adjustable Height Welding Positioner

POA: Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have.

-

0%

Key Plant Automation AHVP1500 1500LB (~700KG) Adjustable Height Welding Positioner

POA: Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have.

-

0%

Key Plant Automation VP50 50 Tonne Fixed Height Welding Positioner

POA: Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have.

-

0%

Key Plant Automation VP35 35 Tonne Fixed Height Welding Positioner

POA: Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have.

-

0%

Key Plant Automation VP20 20 Tonne Fixed Height Welding Positioner

POA: Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have.

-

0%

Key Plant Automation VP15 15 Tonne Fixed Height Welding Positioner

POA: Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have.

Mastering Welding Precision with Welding Positioners and Welding Turn Tables

Welcome to the world of welding excellence! Whether you are a seasoned welder or a novice in the welding industry, having the right equipment is essential to achieve flawless and efficient welds. In this comprehensive guide, we will dive deep into the realm of welding positioners and welding turn tables, two indispensable tools that can elevate your welding experience to a whole new level of precision and productivity.

Understanding Welding Positioners

1. What are Welding Positioners?

Welding positioners are mechanical devices designed to hold, rotate, and manipulate workpieces during the welding process. These innovative tools are specifically engineered to enhance weld quality, increase welding speed, and improve the overall productivity of welders.

2. How Do Welding Positioners Work?

Welding positioners feature a sturdy and adjustable platform that securely clamps the workpiece. The platform can be tilted, rotated, and positioned at various angles, allowing the welder to access hard-to-reach areas with ease. This dynamic control over the workpiece's orientation facilitates better welding joint access, resulting in stronger, more reliable welds.

3. The Advantages of Welding Positioners

Investing in welding positioners offers a plethora of benefits, including:

a) Enhanced Weld Quality: Welding positioners ensure consistent and uniform welds by minimizing operator error and reducing the risk of defects like undercuts and incomplete fusion.

b) Increased Productivity: With the ability to position the workpiece optimally, welders can achieve faster welding speeds, leading to improved productivity and reduced downtime.

c) Ergonomic and Safer Welding: By reducing the need for welders to perform strenuous and awkward welding positions, welding positioners promote better ergonomics, reducing the risk of work-related injuries.

d) Versatility: These devices accommodate a wide range of workpiece sizes and shapes, making them suitable for various welding applications.

Key Features to Look for in a Welding Positioner

When choosing the ideal welding positioner, consider the following key features:

a) Weight Capacity: Select a welding positioner that can handle the weight of your typical workpieces without compromising stability and safety.

b) Rotation Speed and Torque: The rotation speed and torque should match the requirements of your welding projects to ensure smooth and controlled rotation.

c) Control Options: Look for user-friendly control interfaces, such as digital displays and remote controls, to streamline operation.

d) Tilting and Rotation Range: Opt for a positioner with a wide tilting and rotation range to achieve the desired welding angles effortlessly.

Unraveling the Advantages of Welding Turn Tables

1. What are Welding Turn Tables?

Welding turn tables, also known as welding rotary tables, are motorized devices that allow workpieces to rotate 360 degrees continuously. These tables serve as a valuable companion to welding positioners, providing an extra level of rotational freedom to the workpiece.

2. How Do Welding Turn Tables Work?

The workpiece is securely clamped onto the table's surface, and the motor-driven rotation system provides a constant and smooth rotational motion. Welding turn tables are particularly useful for circular welds, enabling welders to achieve consistent and even results.

3. The Benefits of Welding Turn Tables

Incorporating welding turn tables into your welding setup offers numerous advantages, including:

a) Uniform Circular Welds: Welding turn tables guarantee uniform and symmetrical circular welds, avoiding variations in thickness and strength along the weld joint.

b) Time and Labor Savings: When handling circular welds, using a welding turn table significantly reduces the need for manual intervention, saving time and effort.

c) Seamless Integration with Positioners: Welding turn tables can be easily integrated with welding positioners, allowing for multi-axis welding maneuvers and greater flexibility in achieving complex weld joints.

d) Suitable for Various Industries: From manufacturing to construction and beyond, welding turn tables find applications across diverse industries, where circular welding is common.

Frequently Asked Questions about Welding Positioners and Welding Turn Tables

1. What types of welding processes are welding positioners suitable for?

Welding positioners are compatible with various welding processes, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and even arc welding. Their versatility makes them suitable for handling workpieces in industries like automotive, aerospace, shipbuilding, and fabrication.

2. How do welding positioners improve weld quality?

Welding positioners enable welders to maintain a steady arc and control the welding torch's movement effectively. This stability reduces the chance of discontinuities, porosities, and other welding defects, leading to improved weld quality and consistency.

3. Are welding turn tables suitable for large and heavy workpieces?

Yes, many welding turn tables are designed to handle substantial weight capacities, making them suitable for large and heavy workpieces. Manufacturers offer a range of turn table sizes and load capacities to cater to various industrial needs.

4. What safety measures should be taken when using welding positioners and turn tables?

When working with welding positioners and turn tables, it's crucial to follow these safety guidelines:

a) Properly secure the workpiece to prevent any movement during welding.

b) Maintain a safe distance from the rotating workpiece to avoid accidents.

c) Use appropriate personal protective equipment (PPE) such as welding helmets, gloves, and safety glasses.

d) Regularly inspect the equipment for any signs of wear and tear.

Congratulations! You are now well-versed in the world of welding positioners and welding turn tables. These indispensable tools offer a range of advantages, from improved weld quality and productivity to increased safety and versatility. By investing in these innovative devices, you'll elevate your welding capabilities to new heights, leaving a trail of flawless welds and satisfied customers in your wake. Happy welding!